The production of rubber outsoles is a precise process involving both physical and chemical changes, aimed at transforming raw rubber into wear-resistant, slip-resistant, and elastic shoe soles. The main processes are as follows:

1. Internal Mixing

This is the starting point for manufacturing rubber outsoles. The core purpose of internal mixing is to uniformly blend various raw materials under high temperature and pressure. Operators precisely weigh materials according to a specific formula—including natural rubber, synthetic rubber, carbon black (a reinforcing agent), vulcanizing agents (such as sulfur), accelerators, anti-aging agents, softeners, etc.—and feed them into a sealed internal mixer.

Inside the mixer, the materials are thoroughly blended, plastified, and formed into a homogeneous mass of compound through the intense shearing, squeezing, and friction generated by the rotors. This process generates significant heat, making temperature control crucial. The uniformly mixed compound, now a viscous mass, is discharged. It is then passed through an extruder or roller die to form continuous strips or sheets, which are immediately cooled by passing through a water trough. Cooling is essential to prevent the compound from premature vulcanization (scorching) due to residual heat. The cooled compound is cut into sheets of specified dimensions and stored for the next step.

2. Vulcanization

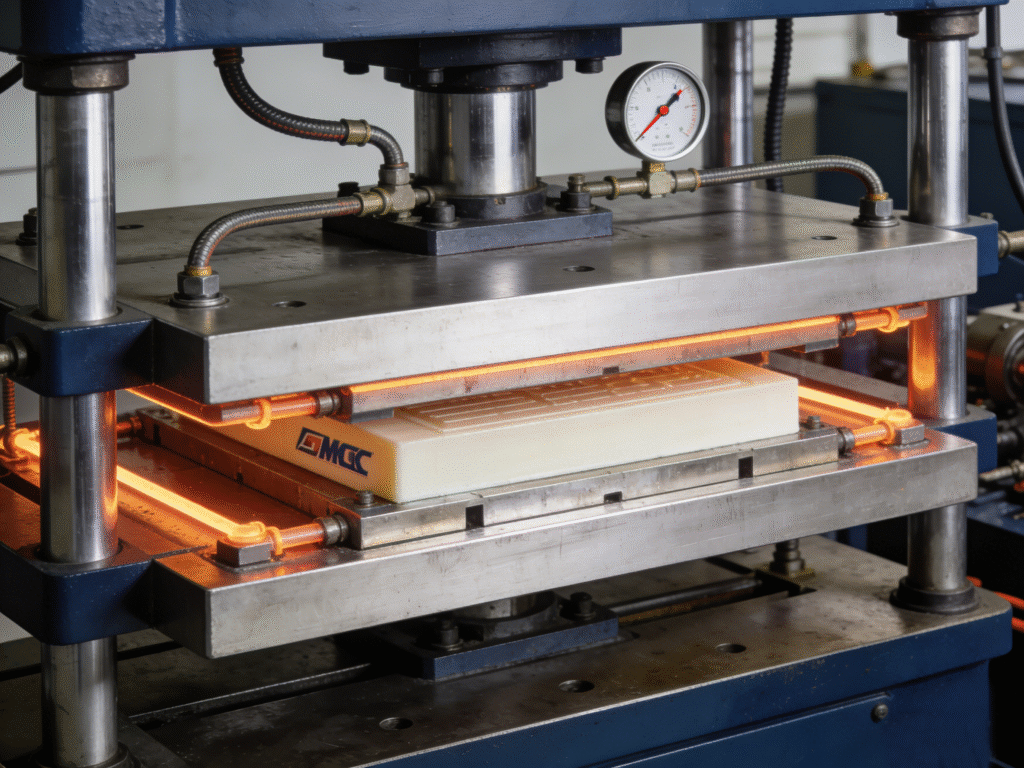

Vulcanization is the key chemical process that imparts the final usable properties to the rubber. The cooled, mixed compound sheets are placed into the metal molds of a plate vulcanizing press. These molds are engraved with the desired sole tread pattern, size, and brand markings.

Inside the vulcanizing press, the compound is heated for a set time under high temperature (typically 140°C-160°C) and high pressure. Under these conditions, the rubber molecular chains form a cross-linked network (“sulfur bridges”) via the vulcanizing agents. This structural change transforms the rubber from a plastic, thermoplastic material into a tough, elastic, and wear-resistant thermoset material. Once vulcanization is complete, the mold is opened, and the formed rubber outsole sheet with clear patterns is removed.

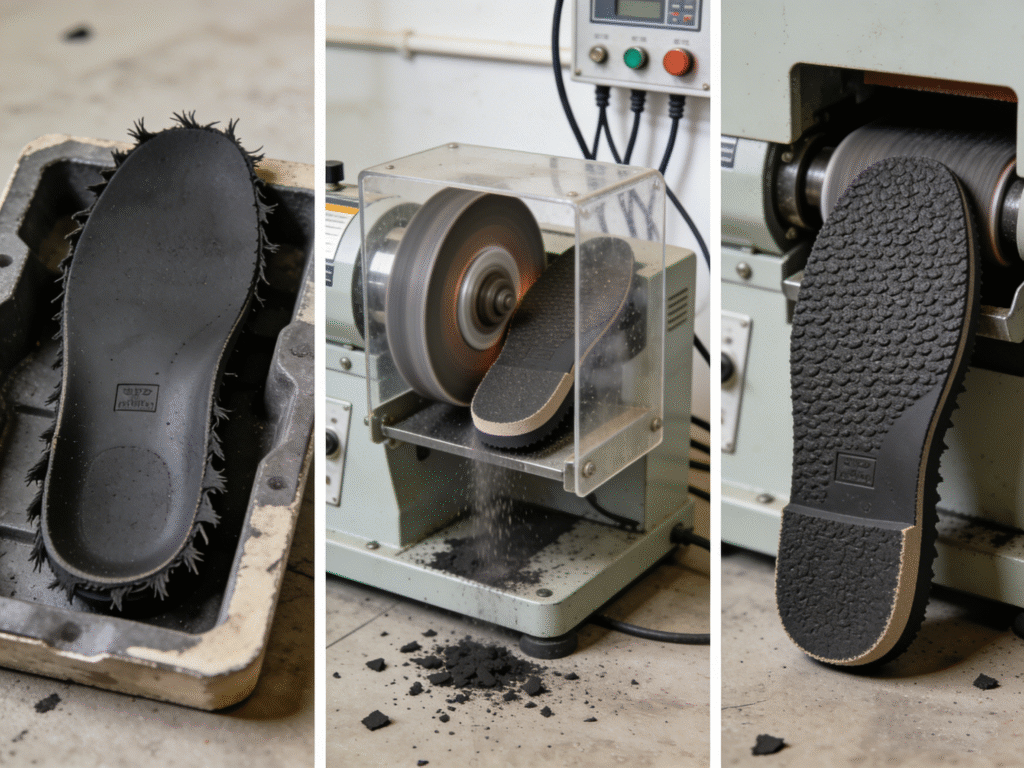

3. Splitting/Roughing to Specified Thickness

The vulcanized outsole sheets taken from the mold may not have perfectly uniform thickness or surface. To ensure the final sole’s thickness precisely meets design specifications, a process called “splitting,” “roughing,” or “calibrating” is required.

In this operation, the vulcanized sole sheets are fed into a specialized calibrating sander or roughing machine. The machine uses high-speed rotating sanding wheels or belts to uniformly grind the backside of the sole (the side that bonds to the upper). This step serves two main purposes: first, it precisely controls the overall thickness of the sole sheet within the customer’s required tolerance; second, it creates a rough, micro-textured surface on the back, which significantly increases the bonding surface area. This results in a stronger and more durable bond when the sole is later attached to the shoe upper.

4. Printing

This is the final key process that meets the customer’s aesthetic requirements. Depending on the design, it may be necessary to print brand logos, patterns, or color lines on the side or specific areas of the sole.

Before printing, the areas of the sole sheet to be printed must be cleaned and surface-treated (e.g., corona treatment) to enhance ink adhesion. Then, using screen printing or other suitable printing techniques, rubber-based ink of specific colors is accurately transferred onto the sole. After printing, the ink may need to be cured—for example, by ultraviolet (UV) light or air drying—to ensure it adheres firmly to the rubber surface and remains resistant to wear and tear during use.

After these four main stages, the production of the rubber outsole is complete. The soles can then undergo quality inspection before being sent to the assembly line for attachment to the shoe uppers.